Manufacturing

In 2020 we introduced the new SRM Series 3-Sided Shuttle Rotomoulding Machine, one of the largest machines of its type, a first for West Coast Poly, & Western Australia. Together with our 3 large twin shuttle machines, our manufacturing prowess is second to none.

West Coast Poly’s state-of-the-art computer systems monitor temperatures, rotations and cook times, so as to ensure each tank is of the highest quality. They have the ability to efficiently control all stages of the production cycle meaning customers receive a product of unmatched finish, strength and durability.

“manufacturing excellence, producing quality polyethylene storage tanks for all applications”

Polyethylene – Our Material

(PE) – Light, versatile synthetic resin made from the polymerization of ethylene. Polyethylene is a member of the important family of polyolefin resins. It is the most widely used plastic in the world, and is considered one of the safest forms of plastic.

LMDPE & HDPE do NOT contain BPA (bisphenol A)

LMDPE

(Linear Medium Density Polyethylene)

The main material for manufacturing our range of products is a hexene grade co-polymer based linear medium density polyethylene. The material offers excellent impact strength and long-term UV stabilisation and is suitable for manufacturing a wide range of products particularly water storage tanks.

LMDPE is compliant with requirements of the Australian Food Contact Regulations AS/NZS 2070:1999, Potable Drinking Water Standards AS/NZS 4020:2018 and certified to AS4766-2020 Standards.

Long term storage is guaranteed using a trusted quality material, ensuring your storage tank stands the test of time and is of the highest quality.

HDPE

(High Density Polyethylene)

A roto-moulding grade of high-density polyethylene is used principally for chemical storage tank applications and is a new generation of hexene HDPE. Ideally suited for manufacturing large storage tanks, the advanced technology of the material leads to superior mechanical properties, high impact strength, high stiffness and long-term UV stabilisation. It is also compliant with AS2070:1999 and AS4766-2020 Standards.

An excellent material choice when considering the long term, safe and secure storage of your chosen liquids.

Process

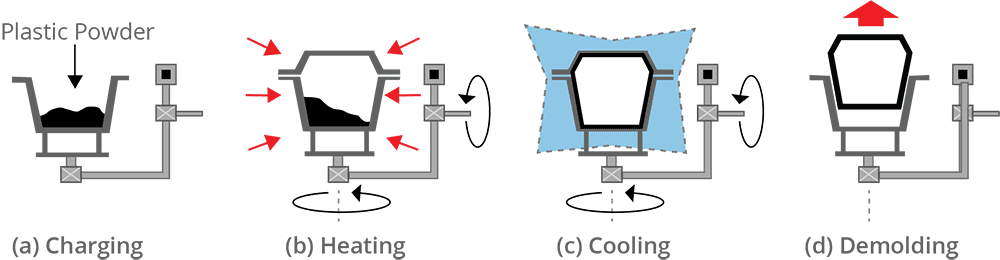

West Coast Poly tanks are produced using the rotomoulding system which allows one piece construction under controlled conditions with a material that is rugged, durable and shows outstanding chemical and environmental resistance.

The process is a four stage system which is inherently efficient:

The polyethylene is tested for dry flow rate and bulk density before a set quantity is loaded into the mould. The mould is then heated while being subjected to multi-directional revolutions so that a specified wall thickness is achieved over the vessel wall. The material is taken to a specified temperature to ensure homogeneity before moving to the cooling phase. The mould continues to rotate during the cooling phase so that it retains its shape.

When the plastic has cooled sufficiently the finished part is removed from the mould and subjected to ultrasonic measurement and low temperature impact testing.

Infrastructure and Machinery

Operating 3 larger twin shuttle machines and also the largest triple shuttle machine within Western Australia STP6500 the company is capable of producing a large tank every 20 minutes. During the manufacturing process the state of the art computer systems monitor temperatures, rotations and cook times to ensure each tank is of the highest quality.

Efficient Factory Design

Quality Machinery

Controlled Environment

While these machines represent a significant investment for the company, their efficiency and ability to control all stages of the production cycle mean that customers receive a product of unmatched finish, strength and durability.